CUSTOM

FIT

—

Every bike, like every rider, is unique so what you’ll see below is just broad strokes for what goes on in a build. We’ll work together to make every detail right and to give you a bike that fits you just right.

The main focus is on keeping the simplicity of the airhead systems but improving reliability, riding comfort, suspension, off-road handling and braking power.

FRONT END

The stock 1980’s telescopic fork end has obvious limitations regarding off-roading on a loaded bike. It’s good on paved roads, but its travel and responsiveness are insufficient in off-road situations.

The builds come with WP Xplor close chamber forks with 250-300mm of travel, depending on riding style and rider’s height.

I developed a robust custom triple tree for mounting the HPN faring and the stock G/S headlight bucket.

The front wheel is a 21” Takasago Excel rim on a Talon aluminum hub and heavy-duty stainless spokes. The wheel axle comes with quick-release handle.

To improve the brake feel and increase stopping power, we fit a 320mm rotor with a 2-piston Brembo caliper and custom stainless steel brake lines.

I also designed a custom bar riser set that moves the handlebars 1.5” higher than stock for a more comfortable standing position.

SUSPENSION —

The final drive is overhauled with new bearings, seals, and gaskets. The rear brake inverted to mitigate damage on rocky roads.

The transmission was completely rebuilt. A longer 5th gear was swapped for better fuel mileage and less load at higher speeds.

The rear 18” Excel Takasago rim was laced with heavy-duty spokes, which require drilling of the BMW hub. For better off-road performance but very capable on pavement, we chose a 130 Mitas E-07. The slight offset of the rim lacing allows the rider to fit up to a 140 tire.

REAR DRIVE

To keep the geometry intact, the swingarm was elongated 100mm, and a custom-length Wilbers shock was fitted, increasing the rear travel.

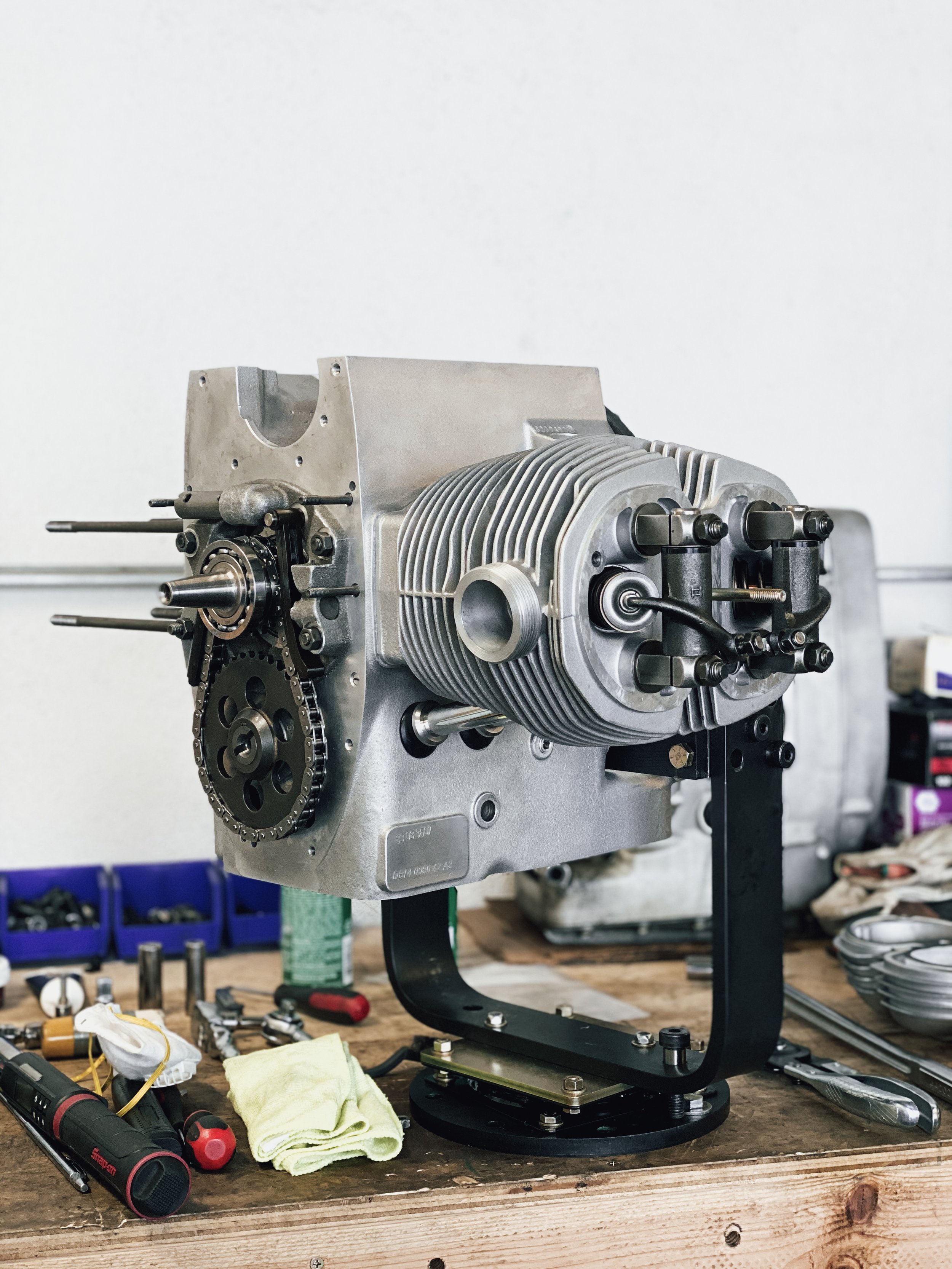

THE ENGINE —

To ensure reliability and longevity, the motor is disassembled and rebuilt from the crank out.

I offer a “stock” 1000cc, 1001cc HC, and 1070cc motors. More power is not always the answer for all applications. I work with my customer to design the most appropriate solution for their use.

When required, the heads are ported to increase engine flow. The airbox was replaced by an open rally air filter and a Siebenrock GS2 exhaust.

The crankshaft, conrods, pistons, and flywheel assembly are all dynamically balanced, making the engine feel smooth and responsive throughout the powerband.

Increased displacement and flow require 40mm carbs. In my experience, Bings are very consistent, fuel-efficient, and fuss-free. The Bings didn’t have a single issue in 168 days on the road to Ushuaia, and for a touring machine, this balance between performance and efficiency is crucial.

COOLING —

Oil coolers are not always necessary on airheads, but when riding loaded under extreme heat conditions (like in Africa) cooling the motor is primordial.

• Rally oil pan ring

• SH Thermostat

• Higher flow oil lines

• High capacity oil cooler

• 6.5mm thick bash plate

COCKPIT —

The goal of this dash design is to make it easy to read and operate while riding and with gloves on.

Our Adventure dashboard reuses the R80ST gauges, but we added a dual-port marine USB hub, custom turn signal bulbs, a hazard light switch, and a second switch if needed.

We also offer Baja style farings and the stock G/S naked headlight bucket with the choice of the PD windshield.

SEAT / RACK —

The main issue with the G/S Paris Dakar solon seats is that the rack is built into the seat. This means you need to unload your duffle to access your tool tray.

We add a built-in rack into the subframe that removes this issue and at the same time it reinforces the whole structure.

LIGHTING —

The stock 1980’s H4 was upgraded with a low consumption, high output self-cooling LED bulb.

Even though you try to never ride at night, sometimes you just have no choice. We picked the Baja Design S1. The S1 utilizes a highly specialized reflector and LED combination. With the 2.1" length, width, and height it’s perfect to mount on the crash bars. The housing is cast aluminum and has been hard anodized & powder coated. With a single LED bulb this tiny light output 2375 lumens each, they are water and shock proof and very light.

LUGGAGE —

We stuck with Hepco Becker because not only is it one of the most solid rack systems but also has a wide range of choices for all types of luggage setups. This is what we rode down to Ushuaia for 20,000 miles without a problem.

In my experience, these are robust, easy to install, remove from the bike, and sit higher than some more vertical case designs. A set of these cases and the built-in luggage rack for a duffle bag is all I would ever need for Overlanding.

-

Myth Adventure

-

Myth Touring